Maintenance

For refrigeration, air conditioning and heat pumps.

Planned Preventative Maintenance

Vectis Refrigeration takes pride in keeping top island businesses going, even in most extreme weather conditions by offering our clients planned preventative maintenance (PPM) programmes.

Planned Maintenance

Condition led, accountable, evidence based system care

Planned maintenance should protect assets, reduce risk, and provide clear accountability. When it becomes a tick box exercise, it fails to do any of those things.

Vectis provides structured planned maintenance programmes for refrigeration, air conditioning, heat pump, and associated mechanical systems across the Isle of Wight.

Our approach is built around system condition, measured performance, and documented evidence, ensuring maintenance decisions are defensible, proportionate, and accountable.

Vectis works solely on the Isle of Wight. Our engineers are island based, and our clients deal directly with the people responsible for maintaining their systems.

There is no mainland call centre, no rotating subcontract labour, and no reliance on ferry services to attend or support sites.

If we maintain your systems, we take responsibility for them.

Our planned maintenance is delivered through a consistent, structured process rather than individual preference or habit.

Each maintenance visit follows a defined inspection framework appropriate to the system type, capturing:

- Asset condition and cleanliness

- Measured operating data where applicable

- Visual and photographic evidence

- Engineer observations and advisories

- Clear identification of emerging risks

Findings are recorded digitally against each asset, building a service history that allows condition and performance to be assessed over time rather than in isolation.

Maintenance decisions are therefore based on evidence and trend, not assumption.

We approach maintenance as engineers first.

Maintenance inspections are structured to assess:

- Physical condition, cleanliness, and accessibility

- Airflow and heat exchange performance

- Electrical integrity and protective devices

- Refrigerant system health where applicable

- Control operation and system behaviour

- Heating or cooling performance under load

Measurements, observations, and photographic evidence are captured consistently. This allows systems to be assessed comparatively over time and provides a clear basis for maintenance and repair decisions.

Our maintenance programmes are developed using a combination of:

- Manufacturer service requirements

- System condition and operating context

- Recognised industry guidance, including SFG20 where appropriate

Rather than applying generic schedules blindly, these standards are used as a reference framework, supported by measured data, photographic evidence, and engineer accountability.

This approach provides defensible maintenance decisions and clear audit trails for clients, facilities managers, and asset owners.

All maintenance reporting is digital, consistent, and practical.

Clients receive:

- Asset specific service records

- Recorded measurements where relevant

- Photographic evidence of system condition

- Engineer observations and advisories

- Clear identification of developing risks

This level of visibility supports informed decision making and removes ambiguity around system condition, responsibility, or scope.

In many environments, maintenance exists primarily to satisfy paperwork. While this may meet contractual minimums, it often provides little insight into system health or emerging risk.

Our maintenance programmes are designed to:

- Reduce unplanned downtime

- Maintain efficiency and operational performance

- Extend asset life

- Support warranty and compliance obligations

- Provide clear audit trails and accountability

Each visit generates structured records that allow system condition and decisions to be traced over time, rather than relying on assumptions or historic schedules.

Correct maintenance is essential for protecting manufacturer warranties and meeting regulatory requirements.

Our maintenance programmes support:

- Manufacturer service expectations

- F Gas and refrigerant handling obligations

- Performance and safety requirements

Clear reporting and evidence led inspections provide reliable documentation when required by manufacturers, auditors, or facilities management teams.

Book Your 2025 System Health Check

Developing intelligence led maintenance

Vectis is developing its internal Wisdom® intelligence framework, designed to improve how maintenance data is captured, compared, and learned from across similar systems.

This allows us to:

- Identify recurring fault patterns

- Recognise early indicators of performance drift

- Improve diagnostic confidence over time

- Challenge assumptions where real world behaviour differs from guidance

While this intelligence layer continues to evolve, its principles already shape how inspections are carried out, recorded, and reviewed today.

This is not automation for its own sake. It is a disciplined way of learning from the field and applying that knowledge consistently.

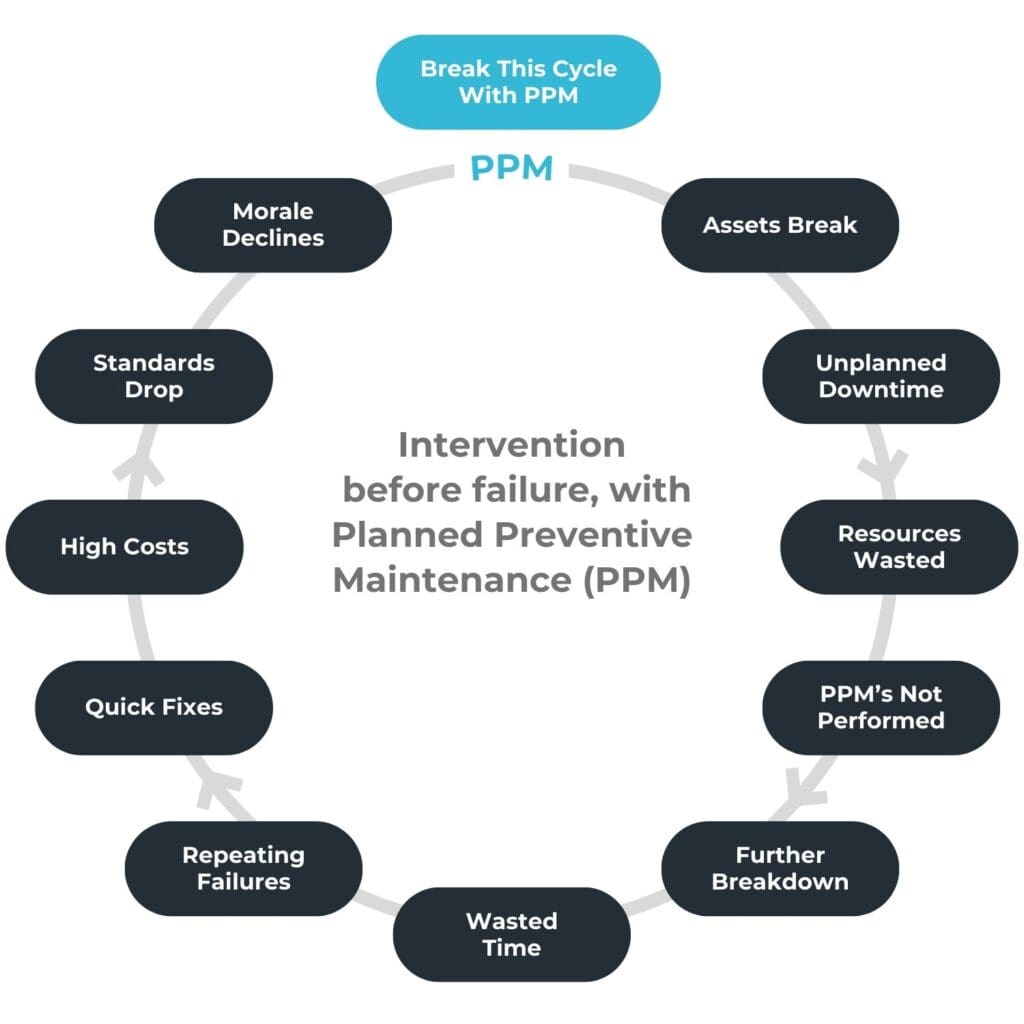

Why choose PPM?

Regular maintenance has 4 key benefits to any business:

Lower Energy Bills

Well maintained commercial refrigeration, air conditioning & heat pump equipment will run with greater efficiency - and your energy bills will show it!

Regular Maintenance

Regular cleaning and maintenance will help to protect machinery susceptible to mould and bacterial growth, making it safe to use without interruption and ensure your customers continue to enjoy top your product.

Longer Lifespan

Protect your considerable investment in your HVACR (Heating, Ventilation, Air Conditioning & Refrigeration) equipment by extending its lifespan.

Reduce Risk of Breakdown

Scheduled checks will significantly reduce your risk of experiencing an unexpected breakdown that will lead to extra product costs and lost business.

What do we offer?

We offer businesses of all sizes Planned Preventative Maintenance (PPM) programs for their commercial HVACR systems.

The PPMs are tailored to each business. Our REFCOM certified engineers keep your systems efficient and FGAS compliant, all year round. Plan’s start from a single visit per year in accordance with the FGAS regulations 2015, however we will advise on the best practise for your business requirements, all arranged to be carried out at your premises for a time that suits you best.

- Planned Preventative Maintenance £150 + VAT

The price for PPM is from £150 plus VAT, We offer discounts for multiple units on a PPM agreement.

- Retainer Package

We also provide a retainer package for clients wishing to have the reassurance of a Vectis Refrigeration engineer at their premises within 4 hours, any time of any day. Business continuity, peace of mind at an affordable price that can be paid in full, or in direct debit instalments.

Industry Standard Maintenance Procedures

We have installed SFG20's industry-standard maintenance procedures into our digital reporting software which can be accessed and compiled by our engineers onsite. SFG20 enables us to offer:

- Industry-standard maintenance requirements needed by refrigeration , air conditioning and HVACR engineers.

- Peace of mind with up-to-date legislative and compliance requirements.

- The latest guidance from dynamically updated content.

- Consistent industry bestp ractice approach around a balanced maintenance regime.

Is a structured maintenance programme right for you?

Planned maintenance works best for organisations that value:

- Accountability over assumptions

- Evidence over reassurance

- Engineering judgement over generic schedules

If you are looking for a maintenance partner who takes system performance, compliance and long term reliability seriously, we are happy to discuss your requirements.

Trusted By